:13688942146

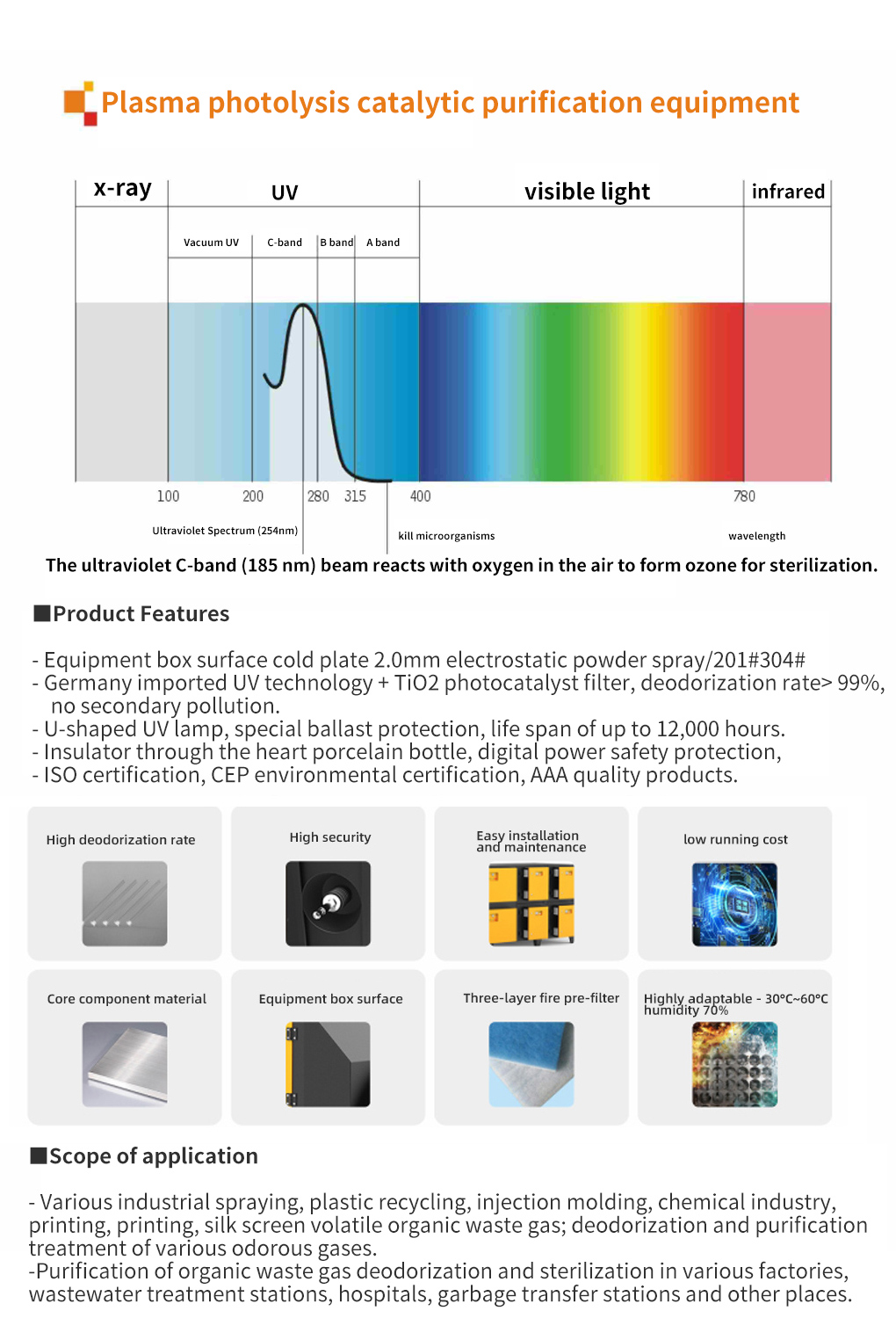

Product features of UV photolysis catalytic purification equipment

1. 2.0mm electrostatic powder spraying of cold plate on the surface of the equipment box/201#304# stainless steel mechanical polishing process

2. Germany imported UV technology + TiO2 photocatalyst filter, deodorization rate> 99%, no secondary pollution

3. U-shaped UV lamp, special ballast protection, lifespan up to 12,000 hours

4. The insulator wears a porcelain bottle, digital power supply safety protection, and equipment personal double insurance

5. ISO certification, CEP environmental certification, AAA quality products

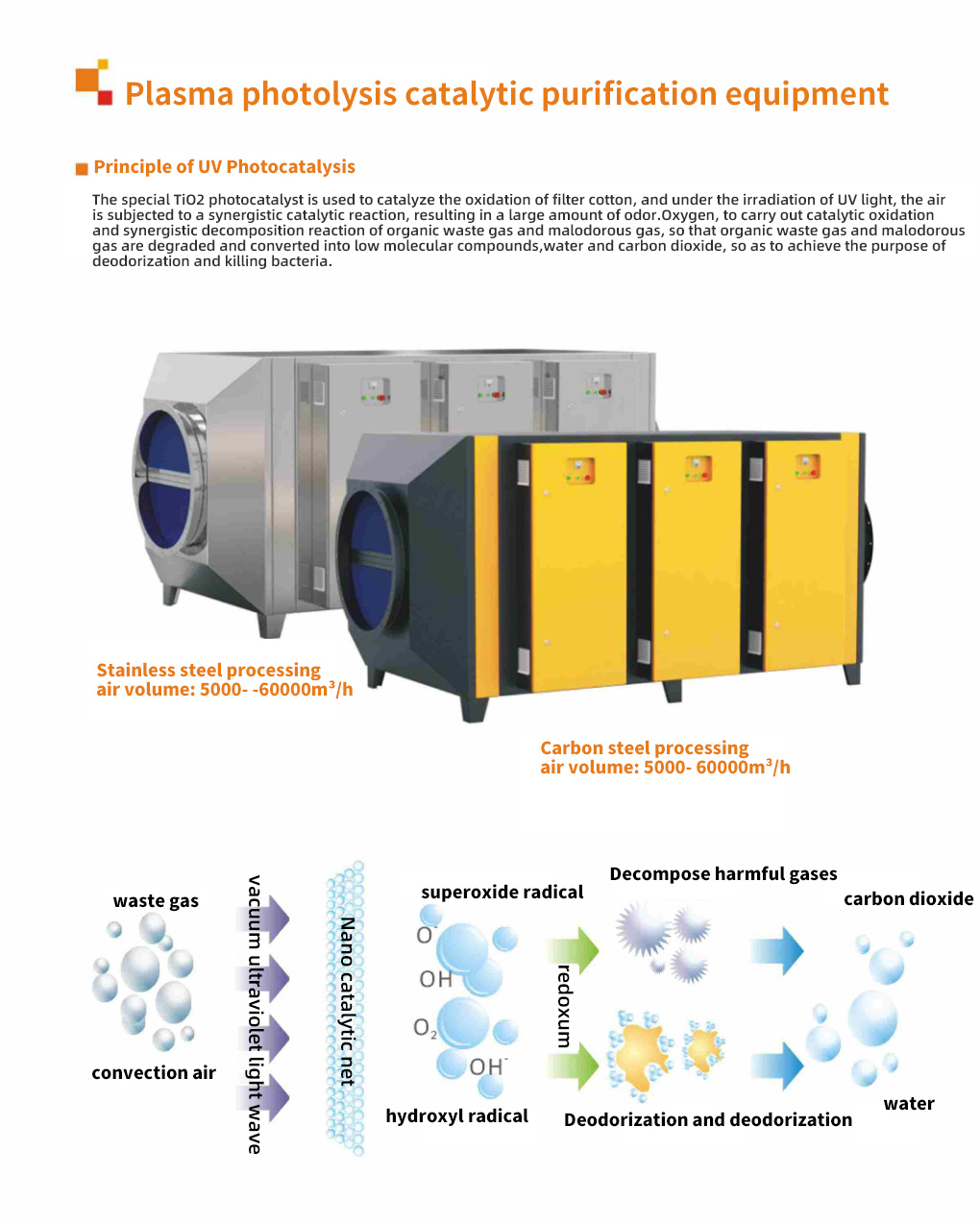

Working principle of UV photolysis catalytic purification equipment

(1) Using a high-energy ultraviolet beam in a special band (157 nm -189 nm) to irradiate organic waste gas and malodorous gases, quickly crack the molecular bonds of exhaust gas and malodorous gases, instantly open and change their molecular structures, destroy their nucleic acids, and produce a series of The photolysis fission reaction re-arranges and combines DNA molecules, degrades them into low-molecular-weight chemicals, such as CO2 carbon dioxide and H2O water molecules.

(2) The use of high-energy ultraviolet light in a special band (157 nm -189 nm) to decompose the oxygen molecules in the air to generate free oxygen, that is, active oxygen, which needs to be combined with oxygen molecules due to the imbalance of positive and negative electrons carried by free oxygen. and then produce ozone); the pollutant molecules in a free state after being cracked by ultraviolet light waves are combined with ozone oxidation to form small molecules of harmless or low-harm compounds. Such as CO2 carbon dioxide molecules, H2O water molecules, etc.

(3) Using special TiO2 titanium dioxide photocatalyst to catalyze the oxidation of filter cotton, under the irradiation of UV ultraviolet light, a photocatalytic reaction is generated, which greatly enhances and strengthens the energy fusion of ultraviolet light waves, and cracks waste gas and odor more efficiently and efficiently. At the same time of odor molecules, it catalyzes the production of more active oxygen and ozone, and conducts a more thorough catalytic oxidation and decomposition reaction for exhaust gas and malodorous odors, so as to degrade and convert them into low molecular compounds, water molecules and carbon dioxide, so as to achieve deodorization and kill bacteria. the goal of.

(4) Efficient deodorization: It can effectively remove volatile organic waste gas (VOCs) and various odors, and the deodorization efficiency can reach more than 99%.

Product advantages

1) High purification efficiency and stable operation.

2), compact structure, novel design, small size, light weight, convenient transportation.

3), noise ≤ 45dB (A), equipment wind resistance ≤ 100Pa.

4), low operating cost and low energy consumption.

5), UV light oxidation decomposition + carbonization technology.

6), easy to install and operate.

7), easy to clean and maintain, long service life.

Scope of application

(1) Wide range of application, suitable for VOCs organic waste gas, non-methane total hydrocarbons, and eight odorous substances (ammonia, hydrogen sulfide, carbon disulfide, methyl mercaptan, methyl sulfide, dimethyl disulfide) specified in the "National Odor Pollution Control Standard" Sulfur, trimethylamine, styrene) and benzene, toluene, xylene and other waste gas can be effectively treated and purified, especially suitable for the treatment of various odorous waste gas, rancid waste gas, paint waste gas, spray waste gas, electrophoresis waste gas, electroplating waste gas, printing and dyeing waste gas, Bio-pharmaceutical waste gas, waste water sewage odor waste gas, sludge odor treatment, etc.

(2) It can treat all kinds of waste gas, including waste gas that is not suitable for plasma treatment (such as paint waste gas, spray waste gas, chemical waste gas, gasoline alcohol waste gas, Tianna water waste gas, paint factory waste gas, fertilizer factory waste gas, etc.), if Using UV photolysis equipment, the safety is higher.

Precautions

1. In order to ensure the purification efficiency of the equipment, the fan should be located behind the exhaust gas purifier.

2. If the exhaust gas purifier is installed on the bracket, it should be tightly connected with the bracket; the connection with the exhaust pipe must be sealed.

3. The exhaust gas purifier should be installed outdoors, with enough space for maintenance and repair; when installing outdoors, a rain-proof and sunshade awning should be installed to avoid affecting the normal service life of the exhaust gas purifier and increasing unnecessary maintenance. cost.

4. In order to ensure the purification efficiency of the exhaust gas purifier, the variable diameter air duct connected to the air inlet and outlet of the equipment should be as smooth as possible.

5. The exhaust gas purifier box should be grounded safely and reliably. It is not allowed to bump the electrodes during the installation process, and foreign objects are strictly prohibited from falling into the purifier.

V1 Environmental Technology Co,. Ltd

Contact: Manager Xie

Phone: 13688942146

Switchboard: 0769-81667033

Email :james@v-1.com.cn

Address: No.5, Jiangbei Xinkang Road, Wusha Village, Changan Town, Dongguan City